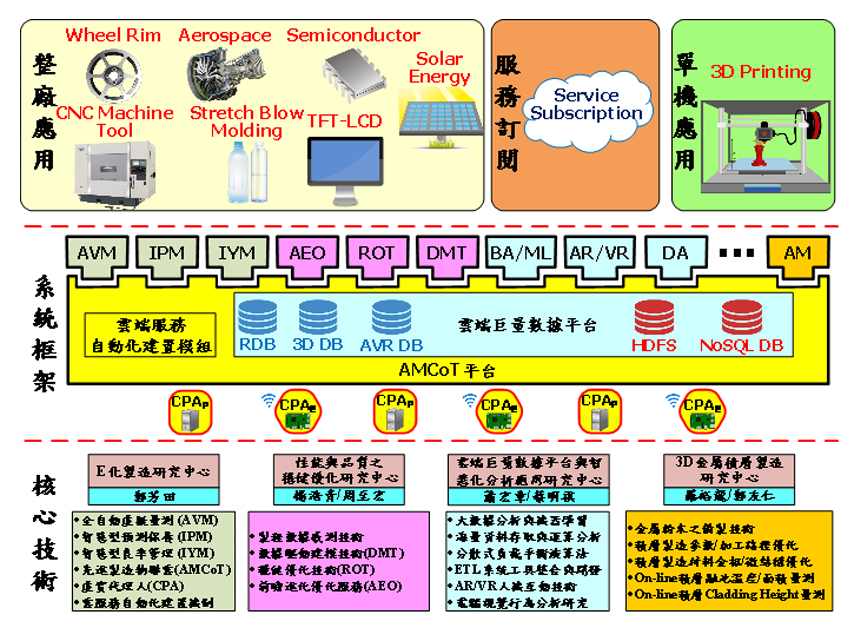

「智慧製造研究中心(iMRC)」之任務分工與系統架構圖如下圖所示

並以不同顏色標示各子計畫之研究範疇。總計畫將負責主導與協調四個子計畫(E 化中心、RO 中心、AM 中心與 IBDI 中心),由各子計畫提供關鍵實現技術共同完成「智慧製造系統」之實作,亦需完成「智慧製造系統」導入台灣製造業,並進而建置智慧製造之生態系,協助國內製造業,如汽車鋁輪圈、工具機、航太、PET 吹瓶機、碳纖維、半導體、太陽能電池、TFT-LCD 面板等產業,達成建構屬於台灣自己的智慧製造生態系及產品接近零缺陷即工業 4.1 之願 景;而且,亦能讓使用者或外部系統透過網路隨需(On Demand)訂閱智慧雲端服務。如此,企業將可以創造新的營運模式,使得此智慧製造系統得以更臻完善。另外,本計畫亦將成立研究服務公司(RSC)以便永續經營。

鄭芳田1976年從國立成功大學電機系畢業後,陸續於1982和1989年在美國俄亥俄州立大學取得電機工程碩士和博士學位。大學畢業後,鄭芳田到國家中山科學研究院任職,直到1995年,轉至成大製造所與資訊工程學系任教,致力將在中科院所磨練出來的自動化與系統整合技術,轉應用於高科技及傳統產業的基於資通訊科技與人工智慧之智慧製造資訊系統領域上,順遂超越工業4.0達成工業4.1即產品零缺陷的目標。為實現工業4.1之零缺陷製造,並響應政府的智慧製造產業創新政策,鄭芳田於2018年在成大創立了智慧製造研究中心(iMRC),並擔任iMRC的中心主任。2024年1月31日鄭芳田屆齡退休,現為iMRC之執行長。

鄭芳田致力於基於資通訊科技與人工智慧之智慧製造和工業4.1的創新研究之成果豐碩,其整合所研發成功之虛實整合代理人物聯網元件(CPA)、先進製造物聯雲(AMCoT)、全自動虛擬量測(AVM)、智慧型預測保養(IPM)、智慧型良率管理(IYM)等相關技術,成功創造出智慧工廠自動化(Intelligent Factory Automation, iFA)雲端服務系統平台;然後,並更進一步地將此iFA系統平台發展為一個可應用於我國製造業之“智慧製造數位孿生(Digital Twins for Intelligent Manufacturing, DTiM)”系統平台,以協助國內產業在面對產業升級及迎合工業4.0浪潮下,達成工業4.0提升產能和監控機台品質與效能等等之基本功能外,亦可超越工業4.0,讓所有產品達到接近零缺陷(Zero Defects)的境界,此境界就是所謂的「工業4.1」。

目前,鄭芳田正規劃將基於過往推展產品接近零缺陷(Zero Defects)之「工業4.1」願景所研發的各項技術能量與研發成果之優勢,再進一步利用先進的資通訊技術(包括:容器虛擬化、物聯網、雲端運算、邊緣運算、即時串流、3D模型、虛擬/擴增實境、區塊鏈、資安防護等)、智慧製造技術(包括:全自動虛擬量測、智慧型良率管理、智慧型預測保養、智慧即時派工、數位孿生等)發展一個『工業4.2–綠色智慧製造系統』,簡稱I4.2-GiM (Industry 4.2 with Green Intelligent Manufacturing)。I4.2-GiM具備系統化碳排管理(如碳揭露、碳減量與碳中和)與智慧化能源管理(如能源消耗預測、智慧廠務能源管理、智慧虛擬電廠等),可藉由數位化、智慧化與可節能減碳的先進科技,幫助我國製造業在滿足數位轉型與智慧製造需求的同時,也能兼顧減碳節能,進而邁向2050淨零碳排(Net Zero)目標,以增強我國製造業的國際競爭力及永續發展。

於應用資通訊科技與人工智慧之智慧製造的領域中,鄭芳田在虛擬量測的學術與應用創新領域上獨步全球,並榮獲六國(中華民國、美、德、日、韓、大陸)之多項發明專利;這些專利已構成一個非常完整的專利地圖,不易被任何研發團隊突破或超越,因此具備極優異的國際競爭力,且已完成59項技術移轉給多家國內高科技及傳統產業大廠。鄭芳田所創的iFA系統平台與其內所包含的CPA, AMCoT, AVM, IPM, IYM,…等技術,可為各式產業(半導體、面板、太陽能、航太、汽機車、橡塑膠、碳纖、模具、N次貼、造紙等) 創造出每年總計超過新台幣壹佰億元以上的產值。該iFA系統平台導入銓寶工業所生產的全世界最快的LSS8直線式全電超高速拉伸吹瓶機後,於2018年8月在台北南港所展出的第16屆台北國際塑橡膠工業展(TAIPEI PLAS 2018)示範展出,且榮獲該屆智慧機械最高榮譽的智慧機械大獎。在2018年台北國際智慧機械暨智慧製造展(iMTduo)中,鄭芳田亦率先向蔡英文總統和當時的沈榮津經濟部長展示應用iFA之全國首創的 “智慧機械雲端服務平台” 來達成工業4.1之目標。

鄭芳田創新的基於資通訊科技與人工智慧之工業 4.1 和智慧製造技術,是成大在全球17項可持續發展目標中之第九大項「工業、創新和基礎設施」名列前茅的主因之一 (由2020年排名第10晉升到2021年名列全球第5,2022持續維持第5名),對成大維持在工程領域執牛耳之領先地位有極大貢獻。在最新的2022年泰晤士高等教育(THE)的影響力排名(Impact Ranking)中,成大已連續三年在台灣排名第1 (2022年成大為台灣第1,全球排名第33)。

根據Clarivate之2022年調查報告顯示,鄭芳田為人工智慧技術專利主要發明人,專利數量最多,且其專利強度評分亦為全國之冠。

鄭芳田曾榮獲的國內外重要榮譽與獎勵有:「行政院2011年傑出科技貢獻獎」、三次科技部(原國科會)之「傑出研究獎」(2006, 2009, 2013年度)、三次經濟部智慧財產局「國家發明創作獎」 (2011, 2012, 2018年度)、2008年經濟部之「大學產業經濟貢獻獎(個人獎)」、教育部2002年度之「大學校院教師產學合作獎」、2010年財團法人東元科技文教基金會之「第十七屆東元獎」、2014年潘文淵文教基金會之「研究傑出獎」、2014年「李國鼎榮譽學者獎」、2015年中華民國斐陶斐榮譽學會第20屆「傑出成就獎」、2022年中華民國自動化科技學會工程獎章、2022年國科會傑出特約研究員、2013年國際電機電子工程師學會Inaba創新引導生產科技獎(IEEE Inaba Technical Award for Innovation Leading to Production)、2008年起為IEEE Fellow & 2021年起為IEEE Life Fellow、2020年起榮膺IEEE CASE Chair of Steering Committee等。此外,自2017年10月起鄭芳田率先成為首位IEEE自動化科學與工程期刊(T-ASE)的中華民國籍Senior Editor。

鄭芳田近期已將上述之與AVM、IPM、IYM、AMCoT、和CPA相關的30篇國際期刊論文系統化地重新整合,以便能編撰成iFA系統平台之文獻資料;再補充一些建構基於資通訊科技與人工智慧之智慧製造系統平台所必備的基礎知識,整合編撰成英文教科書:『Industry 4.1: Intelligent Manufacturing with Zero Defects』,並委由Wiley-IEEE Press在2021年10月26日正式出版全球同步發行。本教科書完整闡述基於資通訊科技與人工智慧之智慧製造的基礎和工業4.1的創新關鍵技術,並分享成功將工業4.0升級至工業4.1之工廠實際運作案例。該書籍可做為所有全世界以基於資通訊科技與人工智慧之智慧製造為重點的高等教育和產業界中研發人員、工程師、學者、與業者等之重要教科書或參考書籍。本書中文版由Wiley-IEEE授權成大出版社於2023年1月出版。

鄭芳田

學歷

| 1972-1976 |

國立成功大學 本國 電機工程系 學士 |

| 1980-1982 |

俄亥俄州立大學 美國 電機工程系 碩士 |

| 1987-1989 |

俄亥俄州立大學 美國 電機工程系 博士 |

經歷

|

1976-1982

|

中山科學研究院電子研究所 研究助理 |

|

1982-1986

|

中山科學研究院電子研究所 助理研究員 |

|

1986-1994

|

中山科學研究院電子研究所 簡聘技正副研究員 |

|

1994-1995

|

中山科學研究院電子研究所 簡聘技監副研究員 |

|

1990-1995

|

中山科學研究院電子研究所 簡聘技監研究員 |

|

1989-1995

|

國立成功大學電機工程研究所 兼任副教授 |

|

1995-1997

|

國立成功大學電機工程研究所 副教授 |

|

1997-2003

|

國立成功大學電機工程研究所 教授 |

|

1998-2001

|

國立成功大學電機工程研究所 教授兼所長 |

|

2003-2008

|

國立成功大學電機工程研究所 特聘教授 |

|

2006-2009

|

行政院國家科學委員會工程處自動化學門 召集人兼主任 |

|

2008-2024

|

國立成功大學E化製造研究中心 中心主任 |

|

2009-2024

|

國立成功大學製造資訊與系統研究所 講座教授 |

|

2011-2024

|

國立成功大學資訊工程學系 講座教授 |

|

2016-2020

|

中華民國自動化科技學會 理事長 |

|

2017-2022

|

Senior Editor, IEEE Transactions on Automation Science and Engineering |

|

2018-2020

|

Award Chair, IEEE Transactions on Automation Science and Engineering |

|

2018-2024

|

國立成功大學智慧製造研究中心 中心主任 |

|

2020-now

|

Chair of Steering Committee, IEEE CASE Conference |

|

2021-now

|

Life Fellow, IEEE |

|

2024-now

|

國立成功大學 名譽講座 |

|

2024-now

|

國立成功大學智慧製造研究中心 研究員 |

|

2024-now

|

國立成功大學智慧製造研究中心 執行長 |

研究領域.

智慧製造、工業4.1、工業4.2、虛擬量測、預測保養、良率管理、智慧工廠自動化 (iFA)

學術及專業協會活動

Associate Editor, IEEE Transactions on Robotics and Automation, 2000-2004

Chapter Chair, IEEE Robotics and Automation Society, Taipei Chapter (2003.08.01 - 2004.07.31)

Finance Chair, IEEE ICRA 2003

Award Chair, Kayamori Best Automation Paper Award, IEEE ICRA 2006

Workshop Organizer & Speaker, “e-Manufacturing for the Semiconductor Industry”, IEEE CASE 2006

Senior Program Committee, IEEE ICRA 2011

Nomination Committee, IEEE RAS Pioneer in Robotics and Automation Award (2012.1.1-2013.12.31)

IEEE RAS Ad Hoc Committee on Automation (2012.1.1-2013.12.31)

Program Co-Chair, IEEE CASE 2013 (August, 2013)

Program Chair, IEEE CASE 2014 (August 18-22, 2014)

Nomination Committee, IEEE RAS George Saridis Leadership Award in Robotics and Automation (2014.01.01~2015.12.31)

Nomination Committee, IEEE RAS Distinguished Service Award (2014.01.01~2015.12.31)

IEEE RAS AdCom Election Committee (2014.01.01~2016.12.31)

Lead Guest Editor, IEEE Transactions on Automation Science and Engineering (2014~2015)

Steering Committee Member, IEEE Conference on Automation Science and Engineering (since 2015)

Nomination Committee, IEEE RAS Fellow (2015.01.01~2017.12.31)

Award Co-Chair, the Inaba Technical Award for Innovation Leading to Production + Robotics and Automation Award for Product Innovation Evaluation Panel (2016.01.01~2017.12.31)

Award Chair, The 12th annual IEEE Conference on Automation Science and Engineering (CASE 2016) (August 21-24, 2016)

Award Chair, 2017 IEEE Conference on Robotics and Automation (ICRA 2017) (May 29-June 3, 2017)

Plenary Speaker, 2017 IEEE Conference on Automation Science and Engineering (CASE 2017) (August 20-23, 2017)

Senior Editor, IEEE Transactions on Automation Science and Engineering (2017-2022)

Award Chair, IEEE Transactions on Automation Science and Engineering (2018-2020)

Evaluation Committee, IEEE RAS Fellow (2018-2020)

Steering Committee Chair, IEEE CASE Conference (since 2020)

Life Fellow, IEEE (since 2021)

Program Chair, IEEE/ASME International Conference on Advanced Manufacturing Technologies and Education in the 21st Century, 2002

Program Co-Chair, IEEE International Conference on Mechatronics, 2005

Guest Editor, “Advanced Integrated Mechatronics”: a Focused Section in IEEE/ASME Transactions on Mechatronics, 2005-2007

Technical Program Chair, IEEE International Student Experimental Hands-on Project Competition via Internet on Intelligent Mechatronics and Automation, 2006

Evaluation Committee, Automation Engineering Program (AEP), NSC, Taiwan, 1998-2001

Planning Committee, AEP, NSC, Taiwan, 1998-2001

Evaluation Committee, Small Business Innovation Research (SBIR) projects, Ministry of Economy Affairs (MoEA), Taiwan, 2002-2005

Awards Chair, The Seventh International Conference on Automation Technology, 2003

Referee, National Invention Competition, Taiwan, 2003-2004

Advisory Board, Automation Technology Foresight Plan, NSC, Taiwan, 2004

Senior Board Member, Chinese Institute of Automation Engineers (CIAE), 2004-2005 & 2009-2014

Evaluation Committee, AEP, NSC, Taiwan, 2004-2007

Planning Committee, AEP, NSC, Taiwan, 2004-2007

Program Chair, International Conference on Hands-on Intelligent Mechatronics and Automation, 2005

Secretary General, Chinese Institute of Automation Engineers (CIAE), 2006-2008

General Chair, The 10th International Conference on Automation Technology, 2009

Program Chair, The 2011 World Congress on Intelligent Control and Automation (WCICA 2011)

President, Chinese Institute of Automation Engineers (CIAE), 2017-2020

榮譽及獎勵

- IEEE ICRA 1999 Kayamori Best Automation Paper Award, IEEE, 1999

- Outstanding Industry-University Cooperation Award, MoE, Taiwan, 2003

- Distinguished Industry-University Professor Award, NCKU, 2004 (for the 1st time)

- Outstanding Industry-University Cooperation Award, NSC, Taiwan, 2006

- Convener & Director, Automation Engineering Program, NSC (2006.12-2009.12)

- Outstanding Research Award (Automation Domain), NSC, Taiwan, 2006 {for the 1st time}

- IEEE Fellow Award, since 2008.01

- Distinguished Industry-University Professor Award, NCKU, 2008 (for the 2nd time)

- Award on University-Industry Economy Contribution – Individual Award, MoEA, Taiwan, 2008

- Chair Professor, NCKU, Taiwan, since 2009.01

- Outstanding Research Award (Domain of Automation), NSC, Taiwan, 2009 {for the 2nd time}

- CIAE Fellow Award, CIAE, Taiwan, since 2010.10

- The 17th TECO Award, TECO Technology Foundation, Taiwan, 2010

- National Invention and Creation Award (Invention Award - Silver Medal), MoEA, Taiwan, 2011

- Award for Outstanding Contributions in Science and Technology, the Executive Yuan, Taiwan, 2011

- National Invention and Creation Award (Invention Award - Gold Medal), MoEA, Taiwan, 2012

- 2013 IEEE Inaba Technical Award for Innovation Leading to Production, IEEE RAS, 2013

- IEEE ICRA 2013 Best Automation Paper Award, IEEE, 2013

- Excellent Teacher Award, NCKU, 2013

- Outstanding Research Award (Domain of Automation), NSC, Taiwan, 2013 {for the 3rd time}

- Outstanding Research Award of Pan Wen Yuan Foundation, Taiwan, 2014

- K.-T. Li Science and Humanities Chair, NCKU, 2014

- 20th Outstanding Achievement Award from the Phi Tau Phi Scholastic Honor Society, Taiwan, 2015

- 2016 Machinery Industry-University Contribution Award of Taiwan Association of Machinery Industry (TAMI), Taiwan, 2016

- 2016 MoST Outstanding Technology Transfer Award, Taiwan, 2016

- IEEE CASE 2017 Best Application Paper Award, IEEE, 2017

- Finalist of ICRA 2018 Best Paper Award in Automation, IEEE, 2018

- National Invention and Creation Award (Invention Award - Silver Medal), MoEA, Taiwan, 2018 {for the 3rd time}

- 2019 Machinery Industry-University Contribution Award of Taiwan Association of Machinery Industry (TAMI), Taiwan, 2019

- 2022 Chinese Institute of Automation Engineers (CIAE) Award, CIAE, Taiwan, 2022

- 2022 Merit NSTC Research Fellow

著作

【Books】

- F.-T. Cheng et al, Industry 4.1: Intelligent Manufacturing with Zero Defects, ISBN: 9781119739890, Publisher: Wiley-IEEE Press, Hoboken, New Jersey, U.S.A., October 2021.

- F.-T. Cheng et al, Industry 4.1: Intelligent Manufacturing with Zero Defects (Traditional Chinese Version), ISBN: 9789865635749, Publisher: NCKU Press, Tainan, Taiwan, R.O.C., January 2023.

【SCI Journals】

- D. E. Orin, C.-K. Tsai, and F.-T. Cheng, “Dynamic Computer Control of a Robot Leg,” IEEE Transactions on Industrial Electronics, vol. IE-32, no. 1, pp. 19-25, February 1985.

- F.-T. Cheng and D. E. Orin, “Efficient Algorithm for Optimal Force Distribution - The Compact-Dual LP Method,” IEEE Transactions on Robotics and Automation, vol. 6, no. 2, pp. 178-187, April 1990.

- F.-T. Cheng and D. E. Orin, “Efficient Formulation of the Force Distribution Equations for Simple Closed-Chain Robotic Mechanisms,” IEEE Transactions on Systems, Man, and Cybernetics., vol. 21, no. 1, pp. 25-32 Jan./Feb. 1991.

- F.-T. Cheng and D. E. Orin, “Optimal Force Distribution in Multiple-Chain Robotic Systems,” IEEE Transactions on Systems, Man, and Cybernetics., vol. 21, no. 1, pp. 13-24, Jan./Feb. 1991.

- F.-T. Cheng, T.-H. Chen, and Y.-Y. Sun, “Resolving Manipulator Redundancy under Inequality Constraints,” IEEE Transactions on Robotics and Automation, vol. 10, no. 1, pp. 65-71, February 1994.

- T.-H. Chen, F.-T. Cheng, Y.-Y. Sun, and M.-H. Hung, “Torque Optimization Schemes for Kinematically Redundant Manipulators,” Journal of Robotic Systems, vol. 11, no. 4, pp. 257-269, June 1994.

- F.-T. Cheng, J.-J. Lee, T.-H. Chen, and F.-C. Kung, “Control and Simulation for a Closed-Chain Dual Redundant Manipulator System,” Journal of Robotic Systems, vol. 12, no. 2, pp. 119-133, February 1995.

- F.-T. Cheng, R.-J. Sheu, and T.-H. Chen, “The Improved Compact QP Method for Resolving Manipulator Redundancy,” IEEE Transactions on Systems, Man, and Cybernetics, vol. 25, no. 11, pp. 1521-1530, November 1995.

- G.-W. Lee and F.-T. Cheng, “Robust Control of Manipulators Using the Computed Torque plus H¥ Compensation Method,” IEE Proceedings Part D, Control Theory and Applications, vol. 143, no. 1, pp. 64-72, January 1996.

- F.-T. Cheng, K.-H. Su, and W.-M. Wang, “Priority Considerations for Multiple Goals of Redundant Manipulators,” Journal of the Chinese Institute of Engineers, vol. 19, no. 4, pp. 499-513, July 1996.

- F.-T. Cheng, T.-L. Hour, Y.-Y. Sun, and T.-H. Chen, “Study and Resolution of Singularities for a 6-DOF PUMA Manipulator,” IEEE Transactions on Systems, Man, and Cybernetics, part B, vol. 27, no. 2, pp. 332-343, April 1997.

- F.-T. Cheng, “An Efficient Method for Obtaining the General Solution for the Force Balance Equations with Hard Point Contacts,” IEEE Transactions on Systems, Man, and Cybernetics, part B, vol. 27, no. 2, pp. 255-260, April 1997.

- F.-T. Cheng and M.-S. Shih, “Multiple-Goal Priority Considerations of Redundant Manipulators,” ROBOTICA, vol. 15, pp. 675-691, 1997.

- F.-T. Cheng, J.-S. Chen, and F.-C. Kung, “Study and Resolution of Singularities for a 7-DOF Redundant Manipulator,” IEEE Transactions on Industrial Electronics, vol. 45, no. 3, pp. 469-480, June 1998.

- F.-T. Cheng, Y.-D. Lu, and Y.-Y. Sun, “Window-Shaped Obstacle Avoidance for a Redundant Manipulator,” IEEE Transactions on Systems, Man, and Cybernetics, part B, vol. 28, no. 6, pp. 806-815, Dec. 1998.

- J.-S. Chen, F.-T. Cheng, K.-T. Yang, F.-C. Kung, and Y.-Y. Sun, “Optimal Force Distribution in Multilegged Vehicles,” ROBOTICA, vol. 17, pp. 159-172, 1999.

- F.-T. Cheng, E. Shen, J.-Y. Deng, and K. Nguyen, “Development of a System Framework for the Computer-Integrated Manufacturing Execution System:a Distributed Object-Oriented Approach,” International Journal of Computer Integrated Manufacturing, vol. 12, no. 5, pp.384-402, September/October, 1999.

- F.-T. Cheng, H.-C. Yang, T.-L. Kuo, C. Feng, and M. Jeng, “Modeling and Analysis of Equipment Managers in Manufacturing Execution Systems for Semiconductor Packaging,” IEEE Transactions on Systems, Man, and Cybernetics, Part B, vol. 30, no. 5, pp. 772-782, October 2000.

- F.-T. Cheng and M.-T. Lin, “Enhancement of Semiconductor Equipment Communications using a Web-enabled Equipment Driver,” IEEE Transactions on Semiconductor Manufacturing, vol. 14, no. 4, pp. 372-380, November 2001.

- F.-T. Cheng and C.-Y. Teng, “An Object-Based Controller for Equipment Communications in Semiconductor Manufacturing,” Robotics and Computer-Integrated Manufacturing, vol. 18/5-6, pp. 371-386, October 2002.

- F.-T. Cheng, H.-C. Yang, and E. Huang, “Development of an Educational Supply Chain Information System Using Object Web Technology,” Journal of the Chinese Institute of Engineers, vol. 25, no. 6, pp. 735-752, November 2002.

- F.-T. Cheng, H.-C. Yang, and C.-Y. Tsai, “Developing a Service Management Scheme for Semiconductor Factory Management Systems,” IEEE Robotics and Automation Magazine, vol. 11, no. 1, pp. 26-40, March 2004.

- F.-T. Cheng, C.-F. Chang, and S.-L. Wu, “Development of Holonic Manufacturing Execution Systems,” Journal of Intelligent Manufacturing, vol. 15, no. 2, pp. 253-267, April 2004.

- F.-T. Cheng, H.-C. Yang, and J.-Y. Lin, “Development of Holonic Information Coordination Systems with Failure-Recovery Considerations,” IEEE Transactions on Automation Science and Engineering, vol. 1, no. 1, pp. 58-72, July 2004.

- M.-H. Hung, C.-H. Tsai, F.-T. Cheng, and H.-C. Yang, “Development of An Ethernet-Based Equipment Integration Framework for Factory Automation,” Robotics and Computer-Integration Manufacturing, vol. 20, issue 5, pp. 369-383, October 2004.

- M.-H. Hung, K.-Y. Chen, R.-W. Ho, and F.-T. Cheng, “Development of an e-Diagnostics/Maintenance Framework for Semiconductor Factories with Security Considerations,” in the Special Issue on Intelligent Maintenance Systems for Int. Journal of Advanced Engineering Informatics, vol. 17, pp. 165-178, October 2004.

- M.-H. Hung, F.-T. Cheng, H.-L. Lee, and D. E. Orin, “Increasing the Stability Margin of Multilegged Vehicles through Body Sway,” Journal of the Chinese Institute of Engineers, vol. 28, no. 1, pp. 39-54, January 2005.

- M.-H. Hung, F.-T. Cheng, and S.-C. Yeh, “Development of a Web-Services-based e-Diagnostics Framework for the Semiconductor Manufacturing Industry,” IEEE Transactions on Semiconductor Manufacturing, vol. 18, no. 1, pp. 122-135, February 2005.

- Y.-C. Su, M.-H. Hung, F.-T. Cheng, and Y.-T. Chen, “A Processing Quality Prognostics Scheme for Plasma Sputtering in TFT-LCD Manufacturing,” IEEE Transactions on Semiconductor Manufacturing, vol. 19, no. 2, pp. 183-194, May 2006.

- Y.-C. Su, F.-T. Cheng, M.-H. Hung, and H.-C. Huang, “Intelligent Prognostics System Design and Implementation,” IEEE Transactions on Semiconductor Manufacturing, vol. 19, no. 2, pp. 195-207, May 2006.

- F.-T. Cheng, Y.-C. Su, and C.-H. Wang, “Development of a Software Tester for Distributed Object-Oriented Systems,” Journal of the Chinese Institute of Engineers, vol. 30, no. 1, pp. 115-131, January 2007.

- M.-H. Hung, T.-H. Lin, F.-T. Cheng, and R.-C. Lin, “A Novel Virtual Metrology Scheme for Predicting CVD Thickness in Semiconductor Manufacturing,” IEEE/ASME Transactions on Mechatronics, vol. 12, no. 3, pp. 308-316, June 2007.

- F.-T. Cheng, H.-C. Huang, and C.-A. Kao, “Dual-Phase Virtual Metrology Scheme,” IEEE Transactions on Semiconductor Manufacturing, vol. 20, no. 4, pp. 566-571, November 2007.

- F.-T. Cheng, Y.-T. Chen, Y.-C. Su, and D.-L. Zeng, “Evaluating Reliance Level of a Virtual Metrology System,” IEEE Transactions on Semiconductor Manufacturing, vol. 21, no. 1, pp. 92-103, February 2008.

- M.-H. Hung, T.-L. Wang, F.-Y. Hsu, and F.-T. Cheng, “Development of an Interface C Framework for Semiconductor e-Diagnostics Systems,” Robotics and Computer-Integration Manufacturing, vol. 24, no. 3, pp. 370-383, June 2008.

- F.-T. Cheng, C.-L. Wang, H.-C. Yang, S.-L. Wu, and C.-Y. Lo, “A Study on Application Cluster Service Scheme and Computer Performance Evaluator,” Journal of the Chinese Institute of Engineers, vol. 31, no. 4, pp. 675-690, June 2008.

- Y.-C. Su, T.-H. Lin, F.-T. Cheng, and W.-M. Wu, “Accuracy and Real-Time Considerations for Implementing Various Virtual Metrology Algorithms,” IEEE Transactions on Semiconductor Manufacturing, vol. 21, no. 3, pp. 426-434, August 2008.

- T.-H. Lin, F.-T. Cheng, W.-M. Wu, C.-A. Kao, A.-J. Ye, and F.-C. Chang, “NN-based Key-variable Selection Method for Enhancing Virtual Metrology Accuracy,” IEEE Transactions on Semiconductor Manufacturing, vol. 22, no. 1, pp. 204-211, February 2009.

- F.-T. Cheng, W.-H. Tsai, T.-L. Wang, J. Y.-C. Chang, and Y.-C. Su, “Advanced e-Manufacturing Model,” IEEE Robotics and Automation Magazine, vol. 17, no. 1, pp. 71-84, March 2010.

- M.-H. Hung, S.-W. Wu, F.-T. Cheng, Y.-Y. Feng, “An Efficient Data Exchange Scheme for Semiconductor Engineering Chain Management System,” Robotics and Computer-Integrated Manufacturing, vol. 26, issue 5, pp. 507-516, October 2010.

- W.-M. Wu, F.-T. Cheng, T.-H. Lin, D.-L. Zeng, and J.-F. Chen, “Selection Schemes of Dual Virtual-Metrology Outputs for Enhancing Prediction Accuracy,” IEEE Transactions on Automation Science and Engineering, vol. 8, no. 2, pp. 311-318, April 2011.

- F.-T. Cheng, J. Y.-C. Chang, H.-C. Huang, C.-A. Kao, Y.-L. Chen, and J.-L. Peng, “Benefit Model of Virtual Metrology and Integrating AVM into MES,” IEEE Transactions on Semiconductor Manufacturing, vol. 24, no. 2, pp. 261-272, May 2011.

- Y.-T. Huang and F.-T. Cheng, “Automatic Data Quality Evaluation for the AVM System,” IEEE Transactions on Semiconductor Manufacturing, vol. 24, no. 3, pp. 445-454, August 2011.

- F.-T. Cheng, H.-C. Huang, and C.-A. Kao, “Developing an Automatic Virtual Metrology System,” IEEE Transactions on Automation Science and Engineering, vol. 9, no. 1, pp.181-188, January 2012.

- W.-M. Wu, F.-T. Cheng, and F.-W. Kong, “Dynamic-Moving-Window Scheme for Virtual-Metrology Model Refreshing,” IEEE Transactions on Semiconductor Manufacturing, vol. 25, no. 2, pp. 238-246, May 2012.

- M.-H. Hung, W.-H. Tsai, H.-C. Yang, Y.-J. Kao, and F.-T. Cheng, “A Novel Automatic Virtual Metrology System Architecture for TFT-LCD Industry based on Main Memory Database,” Robotics and Computer-Integrated Manufacturing, vol. 28, no. 4, pp. 559-568, August 2012.

- F.-T. Cheng, Y.-L. Chen, and J. Y.-C. Chang, “Engineering Chain: A Novel Semiconductor Engineering Collaboration Model,” IEEE Transactions on Semiconductor Manufacturing, vol. 25, no. 3, pp.394-407, August 2012.

- M.-H. Hung, C.-F. Chen, H.-C. Huang, H.-C. Yang, and F.-T. Cheng, “Development of an AVM System Implementation Framework,” IEEE Transactions on Semiconductor Manufacturing, vol. 25, no. 4, pp. 598-613, November 2012.

- C.-A. Kao, F.-T. Cheng, W.-M. Wu, F.-W. Kong, and H.-H. Huang, “Run-to-Run Control Utilizing Virtual Metrology with Reliance Index,” IEEE Transactions on Semiconductor Manufacturing, vol. 26, no. 1, pp. 69-81, February 2013.

- Y.-S. Hsieh, F.-T. Cheng, H.-C. Huang, C.-R. Wang, S.-C. Wang, and H.-C. Yang, “VM-based Baseline Predictive Maintenance Scheme,” IEEE Transactions on Semiconductor Manufacturing, vol. 26, no. 1, pp. 132-144, February 2013.

- F.-T. Cheng and Y.-C. Chiu, “Applying the Automatic Virtual Metrology System to Obtain Tube-to-Tube Control in a PECVD Tool,” IIE Transactions, vol. 45, no. 6, pp. 670-681, June 2013.

- Y.-T. Huang, F.-T. Cheng, Y.-H. Shih, and Y.-L. Chen, “Advanced ART2 Scheme for Enhancing Metrology-Data-Quality Evaluation,” Journal of the Chinese Institute of Engineers, volume 37, issue 8, pp. 1064-1079, published online: May 2014, DOI:10.1080/02533839.2014.912773.

- F.-T. Cheng, C.-F. Chen, Y.-S. Hsieh, H.-H. Huang, and C.-C. Wu, “Intelligent Sampling Decision Scheme Based on the AVM System,” International Journal of Production Research, vol. 53, no. 7, pp. 2073–2088, 2015. DOI: 10.1080/00207543.2014.955924.

- F.-T. Cheng, C.-A. Kao, C.-F. Chen, and W.-H. Tsai, “Tutorial on Applying the VM Technology for TFT-LCD Manufacturing,” IEEE Transactions on Semiconductor Manufacturing, vol. 28, no. 1, pp. 55-69, February 2015.

- H.-C. Huang, Y.-C. Lin, M.-H. Hung, C.-C. Tu, and F.-T. Cheng, “Development of Cloud-based Automatic Virtual Metrology System for Semiconductor Industry,” Robotics and Computer-Integrated Manufacturing, Vol. 34, pp. 30-43, Feb. 2015. DOI: 10.1016/j.rcim.2015.01.005.

- H.-C. Yang, H. Tieng, and F.-T. Cheng, “Total Precision Inspection of Machine Tools with Virtual Metrology,” Journal of the Chinese Institute of Engineers, vol. 39, no. 2, pp. 221-235, DOI: 10.1080/02533839.2015.1091279, published online: Oct 2015.

- H.-C. Yang, H. Tieng, and F.-T. Cheng, “Automatic Virtual Metrology for Wheel Machining Automation,” International Journal of Production Research, vol. 54, no. 21, pp. 6367–6377, DOI: 10.1080/00207543.2015.1109724, published online: Nov 2015.

- F.-T. Cheng, Y.-S. Hsieh, C.-F. Chen, and J.-R. Lyu, “Automated Sampling Decision Scheme for the AVM System,” International Journal of Production Research, vol. 54, no. 21, pp. 6351-6366, 2016. DOI: 10.1080/00207543.2015.1072649.

- C.-C. Chen, Y.-C. Lin, M.-H. Hung, C.-Y. Lin, Y.-J. Tsai, and F.-T. Cheng, “A Novel Cloud Manufacturing Framework with Auto-Scaling Capability for the Machining Industry,” International Journal of Computer Integrated Manufacturing, DOI: 10.1080/0951192X.2015.1125766, vol. 29, issue. 7, pp. 786-804, 2016.

- F.-T. Cheng, H. Tieng, H.-C. Yang, M.-H. Hung, Y.-C. Lin, C.-F. Wei, and Z.-Y. Shieh, “Industry 4.1 for Wheel Machining Automation,” IEEE Robotics and Automation Letters, vol. 1, no.1, pp. 332-339, January 2016. DOI: 10.1109/LRA.2016.2517208.

- F.-T. Cheng, Y.-S. Hsieh, J.-W. Zheng, S.-M. Chen, R.-X. Xiao, and C.-Y. Lin, “A Scheme of High-dimensional Key-variable Search Algorithms for Yield Improvement,” IEEE Robotics and Automation Letters, vol. 2, no. 1, pp.179-186, January 2017. DOI: 10.1109/LRA.2016.2584143.

- M.-H. Hung, Y.-Y. Li, Y.-C. Lin, C.-F. Wei, H.-C. Yang, and F.-T. Cheng, “Development of a Novel Cloud-based Multi-Tenant Model Creation Service for Automatic Virtual Metrology,” Robotics and Computer-Integrated Manufacturing, vol. 44, pp. 174–189, April 2017. DOI: 10.1016/j.rcim.2016.09.003.

- H. Tieng, C.-F. Chen, F.-T. Cheng, and H.-C. Yang, “Automatic Virtual Metrology and Target Value Adjustment for Mass Customization” IEEE Robotics and Automation Letters, vol. 2, issue 2, pp. 546–553, April 2017. DOI: 10.1109/LRA.2016.2645507.

- .-C. Lin, M.-H. Hung, H.-C. Huang, C.-C. Chen, H.-C. Yang, Y.-S. Hsieh, and F.-T. Cheng, “Development of Advanced Manufacturing Cloud of Things (AMCoT)-A Smart Manufacturing Platform,” IEEE Robotics and Automation Letters, vol. 2, no. 3, pp. 1809-1816, July 2017.

- Y.-C. Chiu, F.-T. Cheng, and H.-C. Huang, “Developing a Factory-wide Intelligent Predictive Maintenance System based on Industry 4.0,” Journal of the Chinese Institute of Engineers, vol. 40, no. 7, pp.562–571, Aug 2017. DOI: 10.1080/02533839.2017.1362357.

- F.-T. Cheng, C.-Y. Lin, C.-F. Chen, R.-X. Xiao, J.-W. Zheng, and Y.-S. Hsieh, “Blind-stage Search Algorithm for the Key-variable Search Scheme,” IEEE Robotics and Automation Letters, vol. 2, no. 4, pp. 1840-1847, October 2017.

- H.-C. Yang, Y.-Y. Li, M.-H. Hung, and F.-T. Cheng, “A Cyber-Physical Scheme for Predicting Tool Wear based on Hybrid Dynamic Neural Network,” Journal of the Chinese Institute of Engineers, vol. 40, no. 7, pp. 614–625, October 2017. DOI: 10.1080/02533839.2017.1372223.

- H. Tieng, T.-H. Tsai, C.-F. Chen, H.-C. Yang, J.-W. Huang, and F.-T. Cheng, “Automatic Virtual Metrology and Deformation Fusion Scheme for Engine-Case Manufacturing,” IEEE Robotics and Automation Letters, vol. 3, issue 2, pp. 934-941, April 2018. DOI: 10.1109/LRA.2018.2792690.

- C.-C. Chen, M.-H. Hung, P.-Y. Li, Y.-C. Lin, Y.-Y. Liu, and F.-T. Cheng, “A Novel Automated Construction Scheme for Efficiently Developing Cloud Manufacturing Services," IEEE Robotics and Automation Letters, vol. 3, no. 3, pp. 1378-1385, July 2018. DOI: 10.1109/LRA.2018.2799420.

- C.-Y. Lin, Y.-M. Hsieh, F.-T. Cheng, and Y.-R. Yang, “Interaction-Effect Search Algorithm for the KSA Scheme,” IEEE Robotics and Automation Letters, vol. 3, no. 4, pp. 2778-2785, October 2018. DOI: 10.1109/LRA.2018.2838323.

- H.-C. Yang, T.-H. Tsai, H. Tieng, and F.-T. Cheng, “A Gradual Refreshing Scheme for Improving Tool Utilization,” IEEE Robotics and Automation Letters, vol. 4 , issue 2, pp. 515-522, April 2019.

- C.-C. Chen, M.-H. Hung, B. Suryajaya, Y.-C. Lin, H.-C. Yang, H.-C. Huang, and F.-T. Cheng, “A Novel Efficient Big Data Processing Scheme for Feature Extraction in Electrical Discharge Machining,” IEEE Robotics and Automation Letters, vol. 4, issue 2, pp. 910-917, April 2019.

- Y.-M. Hsieh, C.-Y. Lin, Y.-R. Yang, M.-H. Hung, and F.-T. Cheng, “Automatic Virtual Metrology for Carbon Fiber Manufacturing,” IEEE Robotics and Automation Letters, vol. 4, issue 3, pp. 2730-2737, July 2019.

- H.-C. Yang, M. Adnan, C.-H. Huang, F.-T. Cheng, Y.-L. Lo, and C.-H. Hsu, “An Intelligent Metrology Architecture with AVM for Metal Additive Manufacturing,” IEEE Robotics and Automation Letters, vol. 4, no. 3, pp. 2886-2893, July 2019.

- .-Y. Lin, Y.-M. Hsieh, F.-T. Cheng, H.-C. Huang, M. Adnan, “Time Series Prediction Algorithm for Intelligent Predictive Maintenance,” IEEE Robotics and Automation Letters, vol. 4, no. 3, pp. 2807-2814, July 2019.

- H. Tieng, Y.-Y. Li, K.-P. Tseng, H.-C. Yang, and F.-T. Cheng, “An Automated Dynamic-Balancing-Inspection Scheme for Wheel Machining,” IEEE Robotics and Automation Letters, vol. 5, no. 2, pp. 2224-2231, April 2020.

- Y.-M. Hsieh, R. Lu, J.-W. Lu, F.-T. Cheng, and M. Adnan, “Automated Classification Scheme plus AVM for Wafer Sawing Processes,” IEEE Robotics and Automation Letters, vol. 5, no. 3, pp. 4525-4532, July 2020.

- H.-C. Yang, Y.-L. Chen, and F.-T. Cheng, “A Cloud Manufacturing Service to Control Outsourcing Production,” Journal of the Chinese Institute of Engineers, vol. 43, no. 8, pp. 838-850, September 2020.

- M. Adnan, Y. Lu 1, A. Jones, F.-T. Cheng and H. Yeung, “A New Architectural Approach to Monitoring and Controlling AM Processes,” Applied Sciences, 10(18), 6616, October 2020.

- H.-C. Yang, C.-H. Huang, M. Adnan, C.-H. Hsu, C.-H. Lin, and F.-T. Cheng, “An Online AM Quality Estimation Architecture from Pool to Layer,” IEEE Transactions on Automation Science and Engineering, vol. 18, no. 1, pp. 269-281, January 2021.

- Y.-M. Hsieh, T.-J. Wang, C.-Y. Lin, L.-H. Peng, F.-T. Cheng, and S.-Y. Shang, “Convolutional Neural Networks for Automatic Virtual Metrology,” IEEE Robotics and Automation Letters, vol. 6, no. 3, pp. 5720-5727, July 2021.

- M. Adnan, H.-C. Yang, T.-H. Kuo, F.-T. Cheng, and H.-C. Tran, “MPI-based System 2 for Determining LPBF Process Control Thresholds and Parameters,” IEEE Robotics and Automation Letters, vol. 6, no. 4, pp. 6553-6560, October 2021.

- C.-K. Ing, C.-Y. Lin, P.-H. Peng, Y.-M. Hsieh, and F.-T. Cheng, “Golden Path Search Algorithm for the KSA Scheme,” IEEE Transactions on Automation Science and Engineering, vol. 19, no. 3, pp. 1517-1529, July 2022.

- M.-H. Hung, Y.-C. Lin, H.-C. Hsiao, C.-C. Chen, K.-C. Lai, Y.-M. Hsieh, H. Tieng, T.-H. Tsai, H.-C. Huang, H.-C. Yang, and F.-T. Cheng, “A Novel Implementation Framework of Digital Twins for Intelligent Manufacturing Based on Container Technology and Cloud Manufacturing Services,” IEEE Transactions on Automation Science and Engineering, vol. 19, no. 3, pp. 1614-1630, July 2022.

- Y.-M. Hsieh, T.-J. Wang, C.-Y. Lin, Y.-F. Tsai, and F.-T. Cheng, “Convolutional Autoencoder and Transfer Learning for Automatic Virtual Metrology,” IEEE Robotics and Automation Letters, vol. 7, no. 3, pp. 8423-8430, July 2022.

- F.-T. Cheng, C.-Y. Lee, M.-H. Hung, L. Mönch, J. R. Morrison, and K. Liu, “Special Issue on Automation Analytics beyond Industry 4.0: From Hybrid Strategy to Zero-Defect Manufacturing,” IEEE Transactions on Automation Science and Engineering, vol. 19, no.3, pp. 1472 - 1476, July 2022.

- H.-C. Tran, Y.-L. Lo, H.-C. Yang, H.-C. Hsiao, F.-T. Cheng, and T.-H. Kuo, “Intelligent Additive Manufacturing Architecture for Enhancing Uniformity of Surface Roughness and Mechanical Properties of Laser Powder Bed Fusion Components,” early access, IEEE Transactions on Automation Science and Engineering.

- J. Wilch, B. Vogel-Heuser, J. Mager, R. Cendelín, T. Fett, Y.-M. Hsieh, and F.-T. Cheng, “A Distributed Framework for Knowledge-Driven Root-Cause Analysis on Evolving Alarm Data–An Industrial Case Study,” IEEE Robotics and Automation Letters, vol. 8, no.6, pp. 3732-3739, June 2023.

- T.-H. Tsai, B. Yan, P. B. Luh, H.-C. Yang, M. A. Bragin, and F.-T. Cheng, “Near-Optimal Scheduling for IC Packaging Operations Considering Processing-Time Variations and Factory Practices,” early access (April 2023), IEEE Robotics and Automation Letters.

- Y.-M. Hsieh, C.-Y. Lin, J. Wilch, B. Vogel-Heuser, Y.-C. Lin, Y.-C. Lin, M.-H. Hung, and F.-T. Cheng, “An Intelligent Factory Automation System with Multivariate Time Series Algorithm for Chip Probing Process,” IEEE Robotics and Automation Letters, vol. 8, no. 9, pp. 5464-5471, September 2023.

- H. Tieng, T.-C. Ou, T.-H. Tsai, Y.-Y. Li, M.-H. Hung, and F.-T. Cheng, “I4.2-GiM: A Novel Green Intelligent Manufacturing Framework for Net Zero,” early access (December 2023), IEEE Transactions on Automation Science and Engineering.

專利

【AVM 專利】

- Fan-Tien Cheng, Yu-Chuan Su, Guo-Wei Huang, and Min-Hsiung Hung, “Quality prognostics system and method for manufacturing process,” Taiwan R.O.C. Patent no.: I267012; U.S. Patent no.: 7,493,185 B2; and Japan Patent no.: 4601492.

- Fan-Tien Cheng, Yeh-Tung Chen, and Yu-Chuan Su, “Method for Evaluating Reliance Level of a Virtual Metrology System in Product Manufacturing,” Taiwan R.O.C. Patent no.: I315054 and U.S. Patent no.: 7,593,912 B2.

- Fan-Tien Cheng, Hsien-Cheng Huang, and Chi-An Kao, “Dual-Phase Virtual Metrology Method,” Taiwan R.O.C. Patent no.: I338916; U.S. Patent no.: 7,603,328 B2; Japan Patent no.: 4584295; China Patent no.: 823284, and Korea Patent no.: 10-0915339.{2011 Award for Outstanding Contributions in Science and Technology from the Executive Yuan}{Silver Medal of 2011 National Invention and Creation Award (Invention Award)}

- Fan-Tien Cheng, Hsien-Cheng Huang, Yi-Ting Huang, and Jia-Mau Jian, “System and Method for Automatic Virtual Metrology,” Taiwan R.O.C. Patent no.: I349867; U.S. Patent no.: 8,095,484 B2; Japan Patent no.: 4914457; China Patent no.: 843932; and Korea Patent no.: 10-1098037.{Gold Medal of 2011 National Invention and Creation Award (Invention Award)}{2013 IEEE Inaba Technical Award for Innovation Leading to Production}

- Fan-Tien Cheng, Chi-An Kao, Hsien-Cheng Huang, and Yung-Cheng Chang, “Manufacturing Execution System with Virtual-Metrology Capabilities and Manufacturing System including the Same,” Taiwan R.O.C. Patent no.: I412906; U.S. Patent no.: 8,983,644 B2; and China Patent no.:1464514.

- Fan-Tien Cheng, Chi-An Kao, and Wei-Min Wu, “Advanced Process Control System and Method Utilizing Virtual Metrology with Reliance Index,” Taiwan R.O.C. Patent no.: I427722; U.S. Patent no.: 8,688,256 B2; Japan Patent no.: 5292602; China Patent no.: 1205265; and Korea Patent no.: 10-1335896.

- Fan-Tien Cheng and Wei-Min Wu, “Method for Screening Samples for Building Prediction Model and Computer Program Product Thereof,” Taiwan R.O.C. Patent no.: I451336; U.S. Patent no.: 8,862,525 B2; Japan Patent no.: 5515125; China Patent no.: 2117690;and Korea Patent no.: 10-1440304.

- Haw-Ching Yang, Hao Tieng, Min-Hsiung Hung, and Fan-Tien Cheng, “Method for Predicting Machine Quality of Machine Tool,” China Patent no.: {Silver Medal of 2018 National Invention and Creation Award (Invention Award)}

- Fan-Tien Cheng, Chun-Fan Chen, Jhao-Rong Lyu, and Yao-Sheng Hsieh, “Metrology Sampling Method with Sampling Rate Decision Scheme and Computer Program Product Thereof,” Taiwan R.O.C Patent no.: I539298; U.S. Patent no.: 10,269,660 B2; Japan Patent no.: 6285494; Germany Patent no.: 102016109232; China Patent no.: 3092894; Korea Patent no.: 10-1930420; and Austria Patent Approved on April 23, 2022 under application no.: A50480/2016.

- Chun-Fang Chen, Hao Tieng, Fan-Tien Cheng, and Haw-Ching Yang, “Product quality prediction method for mass customization,” Taiwan R.O.C. Patent no.: I614699; U.S. Patent no.: 10,345,794 B2; and China Patent no.: 4602042.

- Fan-Tien Cheng, Yu-Ming Hsieh, and Jing-Wen Lu, “Method for Predicting Occurrence of Tool Processing Event and Virtual Metrology Application and Computer Program Product Thereof,” Taiwan R.O.C. Patent no.: I742709; U.S. Patent pending under application no.: 17/134,133; and China Patent pending under application no.: 202011561263.1.

- Fan-Tien Cheng, Yu-Ming Hsieh, Tan-Ju Wang, Li-Hsuan Peng, and Chin-Yi Lin, “Virtual Metrology Method using Convolutional Neural Network and Computer Program Product Thereof,” Taiwan R.O.C. Patent pending under no.: 110111380; U.S. Patent pending under no.: 17/329,187; and China Patent pending under no.: 202110458621.4.

【IPM 專利】

- Fan-Tien Cheng, Yao-Sheng Hsieh, Chung-Ren Wang, and Saint-Chi Wang, “Baseline Predictive Maintenance Method for Target Device and Computer Program Product Thereof,” Taiwan R.O.C. Patent no.: I463334; U.S. Patent no.: 10,242,319 B2; Japan Patent no.: 5643387; China Patent no.: 2608456; Korea Patent no.: 10-1518448; and EU Patent no.: 2687935.

- Haw-Ching Yang and Fan-Tien Cheng, “Tool Wear Monitoring and Predicting Method,” Taiwan R.O.C. Patent no.: I640390; U.S. Patent no.: 10,695,884 B2; and China Patent no.: 3810797.

- Chin-Yih Lin, Yu-Ming Hsieh, Fan-Tien Cheng, and Hsien-Cheng Huang, “Predictive maintenance method for component of production tool and computer program product thereof,” Taiwan R.O.C. Patent no.: I708197; U.S. Patent no.: 11,378,946 B2; and China Patent pending under no.: 202010313837.7. {Shortlisted for Secondary Review of 2022 National Invention and Creation Award (Invention Award)}

【IYM 專利】

- Fan-Tien Cheng, Yao-Sheng Hsieh, and Jing-Wen Zheng, “System and Method for Identifying Root Causes of Yield,” Taiwan R.O.C. Patent no. I623830; U.S. Patent no.: 10,935,962 B2; China Patent no.: 3405221, and Korea Patent no. 10-2003961.

- Chin-Yi Lin, Yu-Ming Hsieh, and Fan-Tien Cheng, “System and Method that Consider Tool Interaction Effects for Identifying Root Causes of Yield Loss,” Taiwan R.O.C. Patent no.: I660322; U.S. Patent no.: 10,948,903 B2; and China Patent no.: 5180660.

【AMCoT + CPA 專利】

- Chao-Chun Chen, Min-Hsiung Hung, Po-Yi Li, Yu-Chuan Lin, Yu-Yang Liu, Pei-Chen Lee, and Fan-Tien Cheng, “Automated Constructing Method of Cloud Manufacturing Service and Cloud Manufacturing System,” Taiwan R.O.C. Patent no.: I670672; U.S. Patent no.: 10,618,137; and China Patent no.: 4814983.

- Fan-Tien Cheng, Guo-Wei Huang, Chun-Hung Chen, and Min-Hsiung Hung, “Generic Embedded Device and Mechanism Thereof for Various Intelligent-Maintenance Applications,” Taiwan R.O.C. Patent no.: I225606, U.S. Patent no.: 7,162,394 B2, Japan Patent no.: 4303640.

技術轉移

- Fan-Tien Cheng accomplished 63 contracts in total so far (to high-tech and traditional manufacturers such as tsmc, UMC, ASE, SPIL, CMO, Motech, AIDC, FATEK, ChumPower, FFG, FPG, Hopax, Coral-TAIYI, MIRLE, Fidelis IT Solutions, and Yuen Foong Yu Group, as well as R&D institutes including ITRI and PMC), the total contract amount exceeds US$ 7,508,374 with US$ 2,982,930 being paid. The rest amount will be paid in sections along with the implementation progress.

研究計畫

- Fan-Tien Cheng has 50 projects (13 individual research projects, 11 integrated research projects, 7 industry-university cooperative research projects, 2 research fellow projects) of National Science and Technology Council (NSTC) (used to be Ministry of Science and Technology, MoST & National Science Council, NSC), 1 project of Ministry of Education (MoE), 2 projects of Ministry of Economic Affairs (MoEA), and dozens of industry commission projects, with the total contract amount exceeding US$ 11,550,000.

- Important recent research projects

- “MoE Higher Education Sprout Program: Featured Domain Research Center Program—Intelligent Manufacturing Research Center (iMRC),” MoE, Taiwan, R.O.C., January 2018—December 2022.

- “Advanced Manufacturing Cloud of Things,” Contract nos. MoST 104-3011-E-006-001-, MoST 105-2218-E-006-014-, MoST 106-2218-E-006-005-, MoST 107-2218-E-006-005-, MoST, Taiwan, R.O.C., May 2015—February 2019.

- “Industry 4.1 Scheme for Machine Tools Industry,” Contract no. MoST 105-2221-E-006-255-MY3 MoST, Taiwan, R.O.C., August 2016—July 2019.

- “Commercialization and Business Development Project for the Intelligent Manufacturing Systems of the Machine Tool Industry,” Contract no. 106-EC-17-A-05-S3-038, MoEA, Taiwan, R.O.C., September 2017—August 2019.

- “Advanced Manufacturing Cloud of Things Based on Container Technologies,” Contract nos. MoST 107-2218-E-006-055-, 108-2218-E-006-029-, MoST, Taiwan, R.O.C., December 2018—October 2020.

- “Development of the Intelligent Predictive Maintenance System for Fab-Wide Implementation,” Contract no. MoST 108-2221-E-006-210-MY3, MoST, Taiwan, R.O.C., August 2019—July 2022.

- “Realization of Digital Twins for Intelligent Manufacturing (DTiM) (1/3),” Contract no. MOST 110-2218-E-006-027-, 111-2218-E-006-012-, MOST, Taiwan, R.O.C., June 2021—May 2023.

- “Development of Automatic Virtual Metrology System based on Deep Learning,” Contract no. MOST 111-2221-E-006-200-, MOST, Taiwan, R.O.C., August 2022—July 2023.

- Enhancement of Overall Equipment Effectiveness of Factories – Development of Advanced IPM System for Factory-Wide Implementation,” Contract no. MOST 110-2923-E-006-010-MY3, MOST, Taiwan, R.O.C., October 2021—September 2024.

特邀演講

- In recent years, Fan-Tien Cheng has delivered 117 speeches in total, including 14 international conference keynote speeches, 25 domestic conference speeches, 15 Industrial Development Bureau MoEA subsidized courses, 1 intelligent manufacturing workshop course held by Academia Sinica, 49 speeches at enterprises/companies, and 13 speeches in the universities.

- Recent Important International Speeches

- Invited Speech: “Intelligent Sampling Decision Scheme Based on the AVM System”, 2014 International Symposium on Semiconductor Manufacturing (ISSM 2014), Tokyo, Japan (December 2-3, 2014)

- Invited Speech: “Taiwan 4.1 for Engine-Case Manufacturing & Wheel Machining Automation,” 2016 International Manufacturing Technology Show (IMTS), Chicago, U.S.A. (September 12-17, 2016)

- Invited Speech: “Applying AVM and Advanced Manufacturing Cloud of Things for Wheel Machining Automation,” The 26th Taipei International Machine Tool Show, Taipei, Taiwan, R.O.C. (March 29, 2017)

- Plenary Speech: “Applying AVM & AMCoT for Industry 4.1,” 2017 IEEE International Conference on Automation Science and Engineering (IEEE CASE 2017), Xi’an, China (August 24, 2017)

- Keynote Speech: “Industry 4.1: Intelligent Manufacturing with Zero Defects,” The 18th International Conference on Automation Technology (Automation 2021), Kinmen, Taiwan, R.O.C. (November 12, 2021)

- Invited Speech: “Industry 4.1: Intelligent Manufacturing with Zero Defects,” 2022 UAiTED Industry-Academia Matchmaking Conference, Taipei, Taiwan, R.O.C. (August 13, 2022)

- Keynote Speech: “Industry 4.1 for Zero Defects and Industry 4.2 for Net Zero,” Industrial Trend Forum at 2022 Taiwan International Intelligent Manufacturing Show, Tainan, Taiwan, R.O.C. (November 23, 2022)

- Invited Speech: “邁向零缺陷的智慧製造之路”,D Forum智慧工廠論壇春季巡迴-明日製造、數位轉型 (春季台南場),台南 (March 24, 2023)

- Invited Speech: “工業4.1-實現零缺陷的智慧製造與工業4.2-實現淨零碳排的綠色智慧製造”,台塑第七屆創新發表會,台南 (May 5, 2023)

- Invited Speech: “工業4.1-實現零缺陷的智慧製造與工業4.2-實現淨零碳排的綠色智慧製造”,園區廠商交流座談聯誼會暨5G+XR元宇宙應用技術研發中心場域觀摩,台南 (May 10, 2023)

- Invited Speech: “The Future of Automation—Impacts of AI and Beyond,” Panel Discussion at the 19th IEEE International Conference on Automation Science and Engineering (CASE 2023),紐西蘭 (August 29, 2023)

- Invited Speech: “工業4.1-實現零缺陷的智慧製造與工業4.2-實現淨零碳排的綠色智慧製造”,近代工程技術討論會METS2023,台北 (October 24, 2023)