- New Product

- Intelligent Factory Automation (iFA)

Intelligent Factory Automation (iFA)

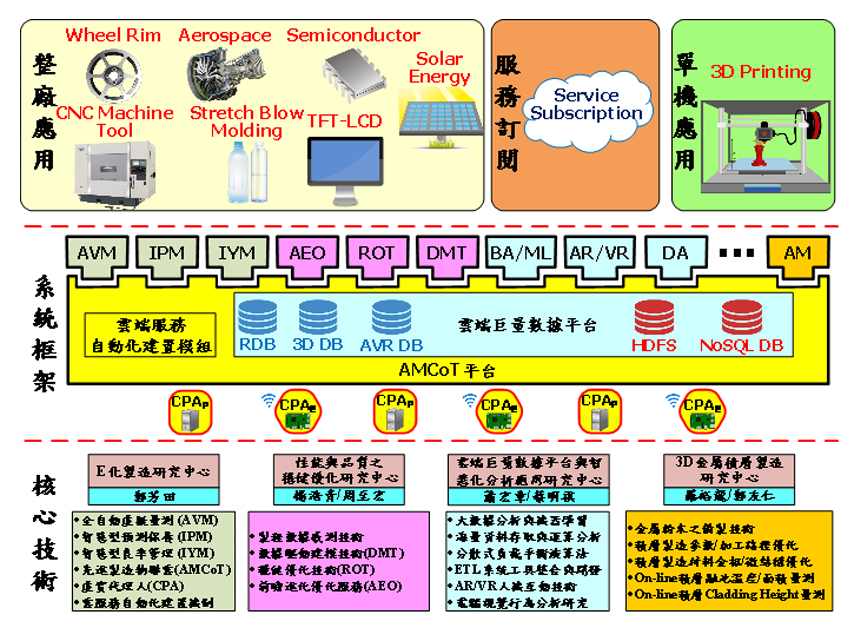

「智慧製造研究中心(iMRC)」之任務分工與系統架構圖如下圖所示

並以不同顏色標示各子計畫之研究範疇。總計畫將負責主導與協調四個子計畫(E 化中心、RO 中心、AM 中心與 IBDI 中心),由各子計畫提供關鍵實現技術共同完成「智慧製造系統」之實作,亦需完成「智慧製造系統」導入台灣製造業,並進而建置智慧製造之生態系,協助國內製造業,如汽車鋁輪圈、工具機、航太、PET 吹瓶機、碳纖維、半導體、太陽能電池、TFT-LCD 面板等產業,達成建構屬於台灣自己的智慧製造生態系及產品接近零缺陷即工業 4.1 之願 景;而且,亦能讓使用者或外部系統透過網路隨需(On Demand)訂閱智慧雲端服務。如此,企業將可以創造新的營運模式,使得此智慧製造系統得以更臻完善。另外,本計畫亦將成立研究服務公司(RSC)以便永續經營。

Intelligent Factory Automation

By integrating technologies such as Cyber-Physical Agent (CPA), Advanced Manufacturing Cloud of Things (AMCoT), Automatic Virtual Metrology (AVM), Intelligent Predictive Maintenance (IPM), and Intelligent Yield Management (IYM), iMRC developed the Intelligent Factory Automation (iFA) System as the core to upgrade Industry 4.0 to Industry 4.1 for realizing the goal of Zero Defects of all products.

There are two options of the iFA System for the customers to choose from.

“Server-based version” and “Cloud-based version” can be provided according to different customer requirements. The contents of the two versions will be illustrated respectively.

Server-based Version

Figure 1

For companies with strong capital or low demand of the cloud, iMRC provides a buyout Server-based version of the iFA System as shown in Figure 1. The Internet of Things (IoT) technology is utilized to develop a Cyber-Physical Agent (CPA) at the machine side. CPA is equipped with various Equipment Drivers for different industries, such as SECS/GEM and Interface A for semiconductor industry, OPC-UA and MT-Connect for machine-tool industry, etc. The Communication Module in CPA is for connecting internet and the cloud. Various intelligent services can be implemented as Pluggable Application Modules (PAMs) and plugged into CPA for edge computing. Then, the Big Data Analytics Applications (BDAA) platform is constructed to include various intelligent manufacturing functions such as Automatic Virtual Metrology (AVM), Intelligent Predictive Maintenance (IPM), Intelligent Yield Management (IYM), Tool Life Management (TLM), Equipment Management System (EMS), etc. AVM can convert offline sampling inspection with metrology delay into online and real-time TOTAL INSPECTION of all the workpieces; IPM can monitor the health status of a key device and predict its remaining useful life (RUL) of the device; IYM is used to quickly find out the root causes that affect the yield; TLM is for online monitoring of cutting-tool status and providing proper tool-change time; and EMS monitors machine utilization and Overall Equipment Effectiveness (OEE).

Cloud-based Version

Figure 2

In view of the fact that many manufacturing industries are small and medium-sized enterprises, their capital is less able to compete with large consortia. To enable the small and medium-size companies to economically adopt the iFA System, we provide the on-demand service subscription as a solution. As long as the companies install their own internet environment, they can save the high cost of building a data center on their own; by just subscribing to our iFA cloud-based services with a relatively low cost of monthly fee. They can access the various intelligent manufacturing services of iFA established on one of the commercialized data centers, such as the Chunghwa Telecom Cloud Data Center.

Due to the nature of different customers’ processes and the requirements of various industries and equipment, the amounts of hardware such as sensors and work-in-process devices, and the scale of hardware implementation have to be determined after on-site field assessment. Therefore, the cost of hardware installation is bundled with the customers and not included in the monthly fee.

The Cloud-based iFA System is shown in Figure 2. CPA is equipped with different equipment drivers for various industries, such as SECS/GEM and Interface A for semiconductor industry, OPC-UA and MT-Connect for machine-tool industry, etc. The Communication Module in CPA, it is for connecting the internet and the cloud. Various intelligent services can be implemented as Pluggable Application Modules (PAMs) and plugged into CPA for edge computing.

Based on the IoT Application platform, which is supported by Chunghwa Telecom, the Advanced Manufacturing Cloud of Things (AMCoT) framework, which includes BDAA platform and Manufacturing Services Automated Construction Scheme (MSACS) is built. Next, on the cloud side, we can utilize a variety of public and private cloud data centers to establish an Advanced Manufacturing Cloud of Things (AMCoT) platform. Additionally, by utilizing relevant cybersecurity protection technologies and hardware firewalls, abnormal activities and external hacking attacks can be prevented to ensure the overall security of the Cloud-based iFA System with the data in confidentiality. The AVM, IPM, IYM, TLM, EMS services can then be added in the AMCoT framework and constructed on the Chunghwa Telecom IoT Application Platform. All the services mentioned above can be made into intelligent cloud services that enable customers around the world to subscribe on-demand and bring a new business model to the enterprises.

The Cloud-based iFA System can provide the intelligence capabilities of improving manufacturing productivity as well as enhancing product quality, and preventing unscheduled down of the production machines as well as reducing the maintenance cost of the machines. As such, the goal of nearly ZERO DEFECTS of all produced products can be achieved efficiently and economically. This is the state of the so-called Industry 4.1 that we defined where the competitiveness and benefits of manufacturing industries can be greatly enhanced.

To learn more about iFA System, please check the following video: